The Packaging Engineering Internship Base of the College of Engineering at Northeast Agricultural University was established at our company.

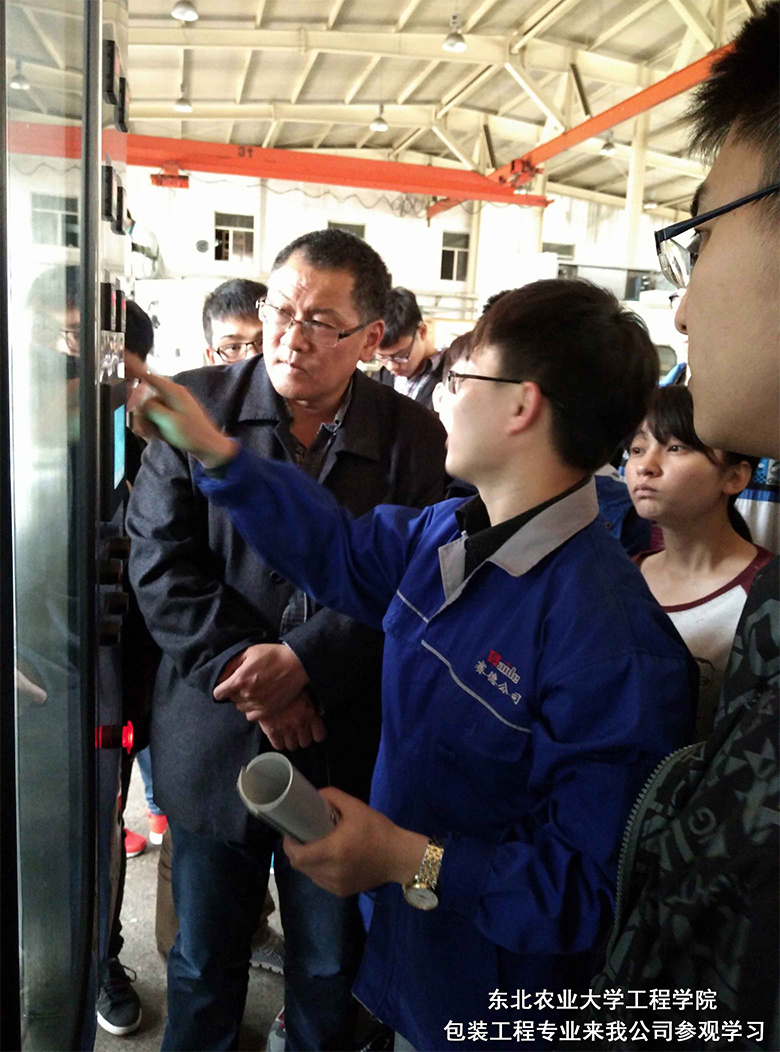

The Packaging Engineering Internship Base of the College of Engineering, Agricultural Engineering University, was inaugurated on May 21 at Harbin Saide Technology Development Co., Ltd. Dr. Zheng Xianzhe, a doctoral supervisor from the College of Engineering, Agricultural Engineering University, led packaging engineering students to visit and study at the company.

The company is located in the Harbin Development Zone, covering more than 10,000 square meters, with brand-new modern production workshops and office environments. The company has strong technical strength, with key personnel being experts from major universities and research institutions. It currently has fixed assets of over 30 million yuan. Since its establishment in 1994, it has been a specialized enterprise focused on the development, production, and operation of various fully automatic packaging equipment. The company always bases itself on technology and market orientation, developing more than twenty types of fully automatic packaging machines in five major series according to domestic and international market demands. These machines are widely used for fully automatic liquid soft packaging in dairy products, condiments, oils, alcoholic beverages, drinks, egg liquid, liquid fertilizers, chemicals, and also for fully automatic soft packaging and automatic metering filling of viscous materials such as sauces (noodle sauce, spicy sauce, bean paste), jams, red bean paste, detergents, lubricants, etc. While absorbing advanced international technology, the products incorporate multiple proprietary patented technologies, with many products maintaining a leading position domestically.

Currently, over a thousand units of products have been applied across various industries nationwide and are highly praised by users. The company has the right to self-import, and its products have been exported to dozens of countries and regions including the United States, the United Kingdom, Russia, Iran, Malaysia, Indonesia, Egypt, Sudan, etc., holding strong competitiveness in the international market.

Led by our company's chief engineer Liu Xiaoye and electrical engineer Ma Chenglong, students toured the factory and were given explanations on the packaging machine structure, electrical control box components, machine principles, and startup operation.

Key explanation of the model 【SJYB-IIIC Grade 100 Clean Side Seal Double-Head Fully Automatic Packaging Machine】

This machine is a high-cleanliness, side-seal, high-speed, double-head fully automatic packaging device specially designed and manufactured for packaging liquids and low-viscosity materials with high shelf-life requirements. The machine is equipped with a grade 100 laminar flow purification device on top, completing the entire packaging process under the positive pressure protection of grade 100 purified air; multiple quartz strong ultraviolet lamps sterilize the packaging film; connected to a CIP system for automatic cyclic cleaning, the hygiene level far exceeds traditional models, thereby extending the shelf life of the packaged products. The equipment can easily switch between different packaging materials.

The machine uses a metering method that adjusts the liquid flow at the end of the supply pipe, which not only ensures accurate measurement but also does not damage the viscosity state of the packaged material. It adopts a combined servo and pneumatic transmission design, PLC control, and a touchscreen human-machine interface. Packaging materials include PE single film, PE co-extruded film, or composite films (PE/PA, PE/PET, PE/AL/PET, etc.). The machine features high cleanliness, wide packaging range, fast packaging speed, high metering accuracy, stable and reliable performance, long service life, simple operation, and easy adjustment.

Main Uses

Suitable for packaging liquids and semi-fluids with high shelf-life requirements, such as fermented yogurt, pasteurized milk, dairy beverages, plant protein drinks, egg liquid, various soups, seasonings, and active biological bacteria.

Technical Performance Parameters: Specification

Production Capacity: 70 ~ 134 bags/min

Packing Volume: 500~100 ml

Production Capacity: 50 ~ 70 bags/min

Packing Volume: 1000~500 ml

Width of Film: 240~330 mm

Accuracy: ±1.5%

Air Pressure: 0.65 Mpa

Air Consumption: 1.0 m³/min (0.8 Mpa)

Power Supply: AC220V±10% 50Hz

Maximum Power: 3.5 KW

Weight: 700 Kg

Dimensions: 1700×1600×3100 (mm)

Air Cleanliness Class: Particulate of 0.3 Micron ≤ 100 particles per cubic foot

TAG:

Previous page

Related news