Product Categories

Contact us

Email: saidepack@163.com

Landline: 86451-84348420

Phone:8613703601493

No.16 Honghu Street, Yingbin Road Concentrated Area, Development Zone, Harbin, China

SJYB-ⅦG(L)/SJYB-ⅧG(L) Type Class 100 Cleanroom Large Capacity Fully Automatic Liquid Packaging Machine with Capping (or Spout) and Stirring

- Product Description

-

SJYB-VIIG(L)/SJYB-VIIIG(L) Type Class 100 Cleanroom Grade Fully Automatic Large Capacity Liquid Packaging Machine with Capping (or Nozzle)

SJYB-VIIL(G)/SJYB-VIIIL(G) Class 100 Cleanroom Grade High-Capacity Fully Automatic Liquid Packaging Machine with Lid/Nozzle

Main Uses

This machine is designed and manufactured as a high-cleanliness, large-capacity fully automatic packaging equipment for liquids and viscous materials that require packaging with capping or nozzle, and have high cleanliness requirements for the packaging environment.

Suitable for packaging the following products:

Salad oil, palm oil and other vegetable oils, soybean paste, sweet flour paste, salad dressings and various sauces, beef bone soup and various soups, soy sauce, vinegar, yellow wine and other liquid seasonings, cream, condensed milk, egg liquid, coconut milk, cold noodle sauce, herbal tea, lubricating oil, liquid fertilizer, coatings, wood varnish, detergents, fabric softeners, bleach, additives, pasteurized milk, yogurt, dairy beverages, fruit juice, drinking water, plant protein beverages, and active probiotics.

Technical Features

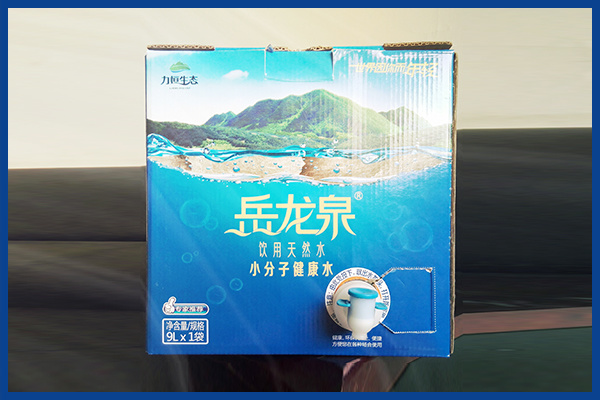

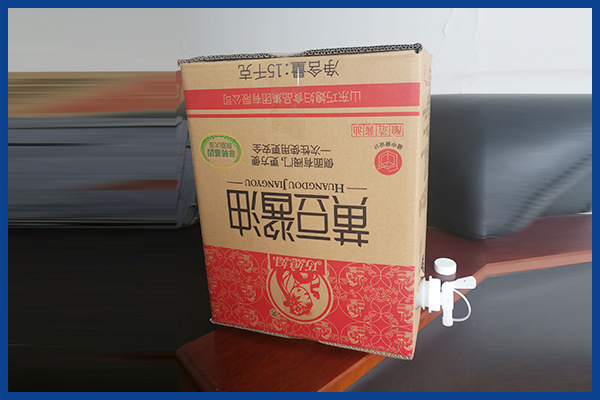

1. Customizable packaging with capping or nozzle; nozzle packaging can be embedded in printed cartons and extracted from the lower side.

2. Customizable packaging capacity: Type VII for 5~12L, or Type VIII for 10~25L.

3. Optional top Class 100 clean laminar flow purification device; the entire machine completes the full packaging process under this purified environment.

4. Lifting horizontal sealing device with stepless adjustment within different height ranges, enabling quick conversion for products of different specifications.

5. Modular design with stainless steel components; transmission combines servo motor and pneumatics.

6. Intelligent control system using PLC and human-machine interface touchscreen.

7. Strong ultraviolet lamps sterilize the packaging film.

8. Supports CIP automatic circulation cleaning system.

9. Packaging material is composite film, with multi-seal blade design to enhance sealing strength.

10. Fully automatic realization of bag making, adding nozzle/cap, filling, metering, sealing, cutting, and date printing throughout the packaging process.

11. The whole machine features high cleanliness, large capacity and adjustment range, high metering accuracy, strong stability, long service life, convenient operation, and flexible adjustment.Technical Performance Parameters

Production Capacity 3~9 bags/min; 2.5~6 bags/min Packaging Capacity 5~12L; 10~25L Film Width 730-810mm or 810-970mm Metering Accuracy ±0.5% Working Pressure 0.65MPa Air Consumption 0.45m³/min (0.8Mpa) Power Supply Voltage AC220V±10% 50Hz Maximum Power of the Whole Machine 3.5KW Overall Dimensions 2920(L)×1750(W)×3200(H)mm Total Weight of the Machine 900Kg Product Video

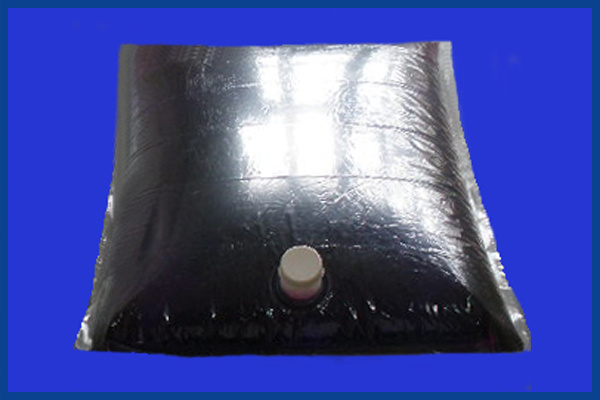

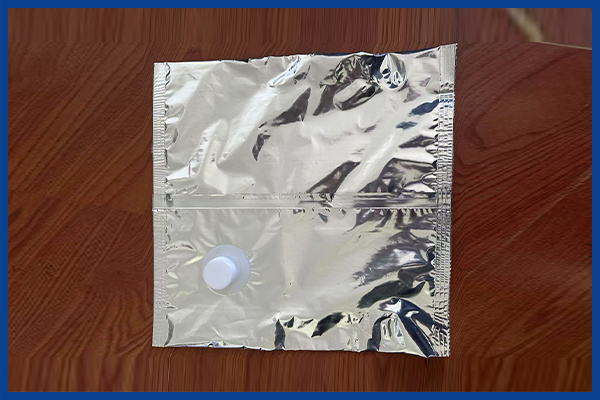

Packaging Samples

Scope of Application

Cooperative Clients

Company Introduction

Harbin Said Technology Development Co., Ltd. was established in 1994, located in Harbin High-tech Industrial Development Zone. It was initiated and established by professors and experts from Harbin Institute of Technology, Harbin University of Commerce, China Aviation Industry Group Aerodynamics Research Institute, and other major institutions. It is a technology-based enterprise integrating "R&D, manufacturing, sales, and service."

The company has been deeply engaged in the field of fluid soft packaging machinery for more than 30 years, providing customers in various industries such as food, oils, agricultural supplies, daily chemicals, and chemicals with one-stop solutions for fully automatic soft packaging of liquids and viscous materials. It has developed more than ten varieties across five major series of fully automatic packaging machines, featuring reliable operation, simple operation, easy maintenance, high metering accuracy, energy saving and environmental protection, covering the full packaging range from 0.1L to 25L to meet the diverse needs of customers.

Keywords:

Get More Product Information

*Note: Please fill in the information accurately, we will contact you as soon as possible.

Related Products

SJGT-II Type Class 100 Clean Fruit Particle Online Addition Dynamic Mixing System