Product Categories

Contact us

Email: saidepack@163.com

Landline: 86451-84348420

Phone:8613703601493

No.16 Honghu Street, Yingbin Road Concentrated Area, Development Zone, Harbin, China

Liquid Flexible Packaging Machine for Vegetable Oils: Palm Oil, Soybean Oil, Salad Oil, and Fat Filling Machine

- Product Description

-

SYB-VI/SJYB-VI Type Fully Automatic Liquid Packaging Machine / Class 100 Cleanroom

-- Fully Automatic Packaging Machine for Vegetable Oils: Palm Oil, Soybean Oil, Salad Oil—Oil Filling Machines Available in Customized Capacities to Meet Your Needs

Main uses

This machine is a fully automatic packaging device designed and manufactured specifically for packing liquids and viscous materials.

Suitable for packaging the following products:

Animal and vegetable fats and oils such as butter, lard, salad oil, and palm oil; various sauces including doubanjiang, sweet bean sauce, and mayonnaise; diverse soups like beef bone broth; liquid seasonings like soy sauce, vinegar, and rice wine; creamy products, condensed milk, egg liquids, coconut milk, cold noodle sauces, herbal teas, alcoholic beverages, lubricants, liquid fertilizers, paints, wood finishes, detergents, fabric softeners, bleaching agents, food additives, pasteurized milk, yogurt, dairy-based beverages, fruit juices, bottled drinking water, plant-protein drinks, and active probiotic cultures—among others.

Technical features

1. Optionally equipped with a top-level Class 100 laminar flow purification system, the entire machine completes the full packaging process within its purified environment.

2. The lifting and cross-sealing device features stepless adjustment across various height ranges, enabling quick product specification changes.

3. Modular design, stainless steel components, and a hybrid drive system combining servo motors with pneumatic actuation;

4. Utilizes intelligent control systems such as PLC and human-machine interface touch screens;

5. Sterilize the packaging film using a high-intensity UV lamp;

6. Supports the CIP automatic cleaning circulation system;

7. The packaging material is a composite film, featuring a multi-stage sealing design to enhance sealing strength.

8. Fully automated process for bag making, filling, metering, sealing, cutting, and date printing—covering the entire packaging workflow;

9. The complete machine features high cleanliness, large capacity and adjustment range, fast operating speed, precise metering accuracy, strong stability, long service life, convenient operation, and flexible adjustments.Technical Performance Parameters

Production capacity 5–20 bags/min Package Capacity 5~1L Film width 350-620mm Measurement accuracy ±0.5% Work stress 0.65MPa Gas consumption 0.6 m³/min (0.8 MPa) Power supply voltage AC 220V ±10% 50Hz Maximum power of the entire machine 3KW/2.5KW External dimensions 1560(L) × 1550(W) × 2700(H) mm / 3100 mm Overall machine weight 670 kg / 710 kg Product Video

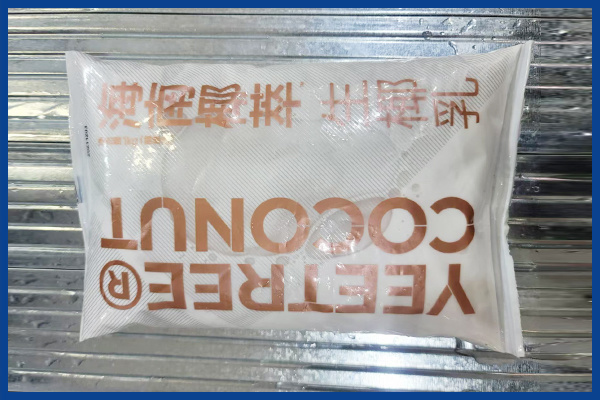

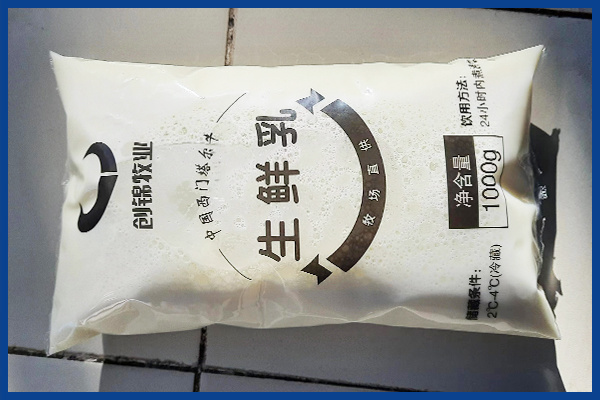

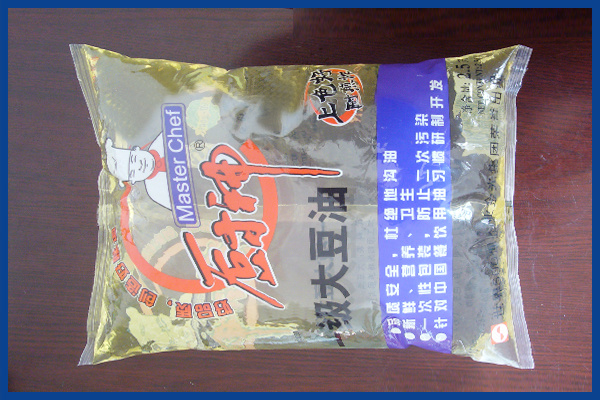

Packaging samples

Scope of Application

Partner Clients

Company Introduction

Harbin Said Technology Development Co., Ltd. was established in 1994, located in Harbin High-tech Industrial Development Zone. It was initiated and established by professors and experts from Harbin Institute of Technology, Harbin University of Commerce, China Aviation Industry Group Aerodynamics Research Institute, and other major institutions. It is a technology-based enterprise integrating "R&D, manufacturing, sales, and service."

The company has been deeply engaged in the field of fluid soft packaging machinery for more than 30 years, providing customers in various industries such as food, oils, agricultural supplies, daily chemicals, and chemicals with one-stop solutions for fully automatic soft packaging of liquids and viscous materials. It has developed more than ten varieties across five major series of fully automatic packaging machines, featuring reliable operation, simple operation, easy maintenance, high metering accuracy, energy saving and environmental protection, covering the full packaging range from 0.1L to 25L to meet the diverse needs of customers.

Keywords:

Get More Product Information

*Note: Please fill in the information accurately, we will contact you as soon as possible.

Related Products

SJGT-II Type Class 100 Clean Fruit Particle Online Addition Dynamic Mixing System