The development trend of packaging machinery brings an efficient life

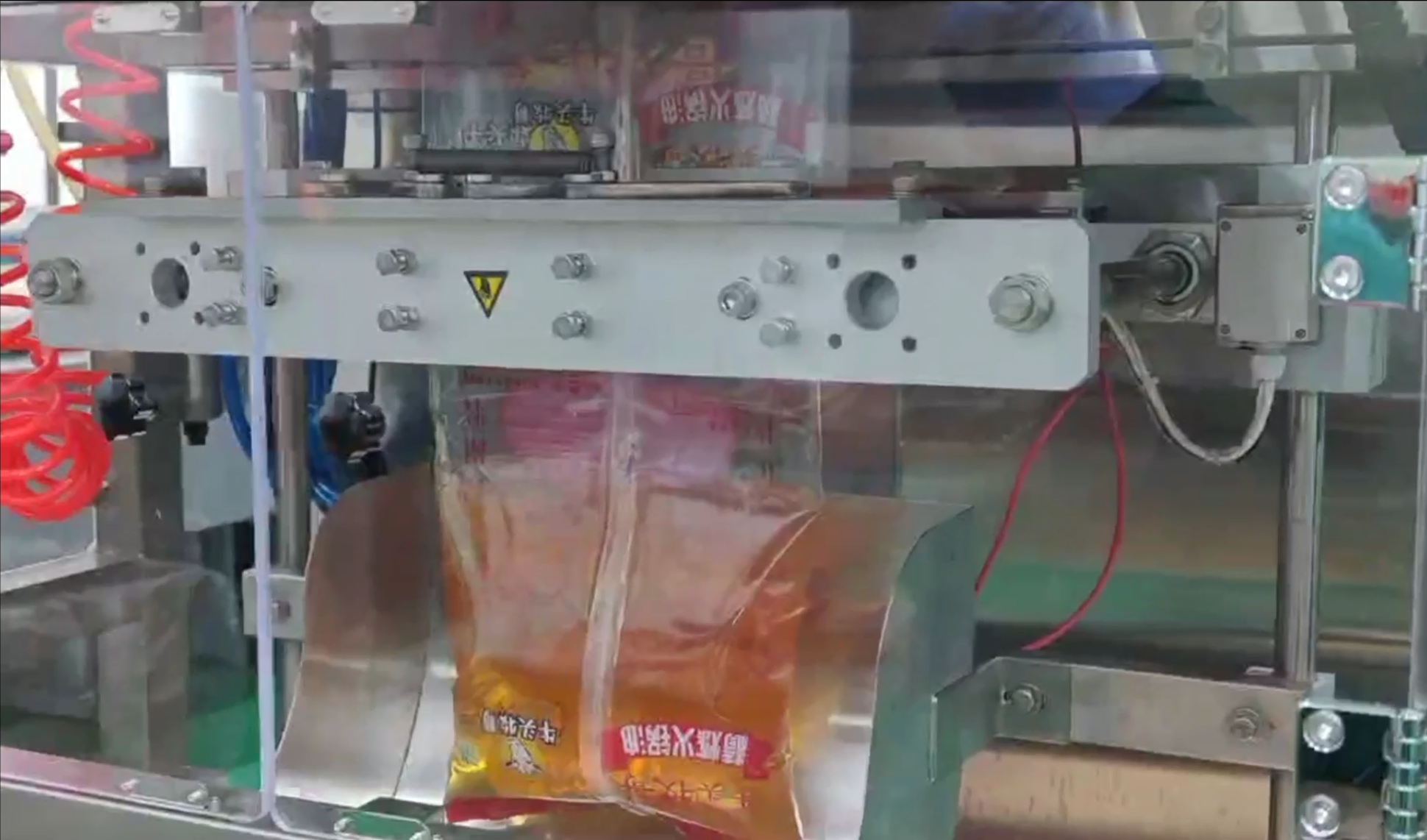

Under the continuous efforts of many packaging machinery manufacturers, domestic packaging machinery has achieved good results in manufacturing, metering, and technical performance, with features such as complete sets, speed, high automation, and excellent reliability.

Considerations for Packaging Machinery Upgrades

It is reported that behind the rapid development of China's packaging industry, a large number of high-tech complete sets of equipment still rely on imports, with a significant amount of foreign exchange spent annually on importing high-end complete equipment. For example, plastic film biaxial stretching equipment costs nearly 100 million yuan per production line. Since its introduction in the 1970s, China has imported 110 such production lines. In addition, aseptic packaging boxes and filling equipment widely used in the dairy industry are almost all supplied by a foreign company.

In recent years, the demand for packaging machinery in various industries in China has been increasing year by year. Although there are many domestic packaging industries, nearly a hundred types of packaging machinery in China still cannot meet the needs of many industries. Therefore, domestic packaging machinery should actively seek better development paths from the demands of related industries, and improving the applicability of packaging machinery is also a good coping strategy.

At the same time, global packaging machinery has also entered a new stage of upgrading.

According to the U.S. Census Bureau's forecast, the United States will enter an aging society by 2025. The U.S. packaging industry fully considers the potential needs of elderly consumers for packaging products and has begun developing packaging adapted to the characteristics of a future aging society, such as zipper-type seals and easy-to-open metal top double finger pull rings. The packaging industry is committed to providing consumers with more convenient packaging.

Packaging in the Palm of Life

With the development of technology, laptops are becoming thinner, phone screens are getting larger, and the "light" era—mobile apps, WeChat, Weibo, and other mobile products—quietly enters our lives, constantly influencing our behavior.

With the rapid development of mobile internet, people's daily access to industry information and business opportunities has extended from traditional internet to mobile internet. Mobile information applications represented by Weibo and apps are changing people's work habits and promoting the development of marketing in various industries.

Now, the use of the internet and social media is common across all age groups. Young people are the largest users of the internet and social media, but usage among older adults in the U.S. is also steadily increasing. According to a Pew Internet research report, 87% of adults use the internet. Among those aged 65 and older, 57% are internet users. Studies show that since 2009, social media use among online seniors has tripled. Digital technology is no longer just for the young. For traditional packaging companies, mobile applications effectively promote interaction between companies/brands and customers, enhancing customer loyalty.

Packaging Machinery Still Has Shortcomings

In recent years, there remains a significant gap between China and advanced foreign levels, urgently needing improvement. When investment in research and development accounts for 1% of a company's sales, the company struggles to survive; at 2%, it can barely maintain; at 5%, it becomes competitive. However, the average investment in research and development by Chinese food packaging equipment companies is still less than 1%.

Statistics show that national R&D funding accounts for only 0.3% to 0.5% of corporate sales revenue, R&D personnel account for only 3.4% to 4% of employees, and research institutes and universities have outdated experimental conditions. Compared with foreign R&D investment levels, China's investment is seriously insufficient, resulting in low automation levels in the food equipment industry and poor market satisfaction; many single machines but few complete sets; many main machines but few auxiliary machines; many low-tech products but few high-tech, high value-added, and high productivity products; many primary processing devices but few deep processing devices; many general models but few special models for special requirements or materials. Compared with similar foreign products, product performance is lower, production capacity is low, and energy consumption is high—on average 4 to 6 times that of developed countries. The performance gap is even greater for large complete sets of equipment; the production capacity of relatively advanced domestic models is about half that of advanced foreign models. Overall, China's food equipment technology level lags behind developed countries by about 20 years.

Since its establishment in 1994, Harbin Saide Technology Development Co., Ltd. has been a specialized enterprise focused on the development, production, and operation of various fully automatic packaging equipment.|Harbin Saide Technology Development Co., Ltd.|Packaging machines|Egg liquid packaging machines|Paraffin packaging machines|Sauce packaging machines|Large bag liquid packaging machines|Milk packaging machines|Bagged water packaging machines|Butter packaging machines|Salad dressing packaging machines|Sweet flour paste packaging machines|Detergent packaging machines|Oil packaging machines|Soy sauce packaging machines|Yogurt packaging machines|Butter packaging machines|Cream packaging machines|Pasteurized milk packaging machines|Lubricating grease packaging machines|Bagged milk packaging machines|Bagged soy sauce packaging machines|Bagged vinegar packaging machines|Refined oil packaging machines|Bag-in-box packaging machines

Actually, the urgency is not immediate, and the problems packaging machinery needs to solve are not unique to China. German packaging machinery, especially food packaging machinery, features high-speed complete sets, high automation, and good reliability. Increasing machine speed is a complex issue; the faster the speed, the lower the unit production cost, but the factory floor area increases accordingly. Moreover, motor speed has limits, so it cannot be increased arbitrarily. Generally, increasing speed by 15% to 20% brings a series of complex problems.

TAG:

Next page

Related news