Said Fully Automatic Liquid Soft Packaging Machine: A One-Stop Solution Empowering Flexible Production Across Multiple Product Categories

Said Fully Automatic Liquid Soft Packaging Machine: A One-Stop Solution Empowering Flexible Production Across Multiple Product Categories

Core keywords: Said Fully Automatic Packaging Machine, Liquid Soft Packaging Machine, Multi-Functional Packaging Equipment, Packaging Production Line

Said Bagged Liquid Fully Automatic Packaging Machine It’s not designed for a single product—instead, it’s a true “all-rounder,” dedicated to meeting your fully automated, high-standard packaging needs for a wide variety of fluid products with just one machine.

I. Core Positioning: What Is the Saide Fully Automatic Liquid Soft Packaging Machine?

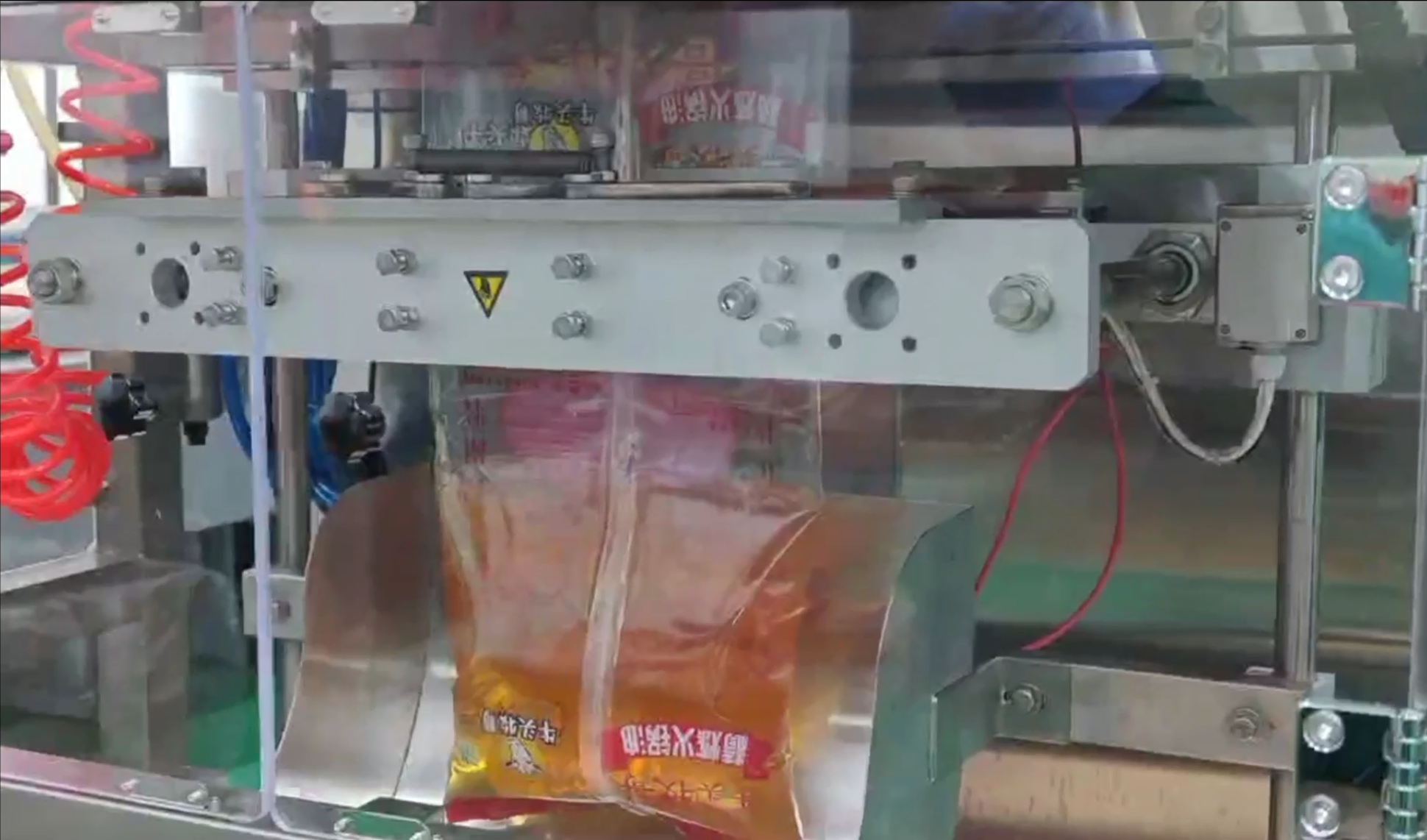

The Saide fully automatic liquid soft packaging machine is a highly integrated, flexible packaging system. It is specifically designed for Liquids, semi-fluids, and viscous materials Design capable of automatically completing the process from roll film material to finished product output. Bag making, weighing and filling, sealing and cutting, date printing The entire process. Its core value lies in "Multi-purpose in one device" With "Smart and Efficient" , providing customers with multi-category production unprecedented flexibility and cost-effectiveness.

II. Four Outstanding Application Features: Unveiling How They Make It a "Jack of All Trades"

How does this device effortlessly handle a variety of products, from whipped cream to soy sauce and vinegar? Its core competitiveness stems from the following four key features:

1. Exceptional Flexible Production Capability

Core Technology : Unique Lifting and Horizontal Sealing Device 。

Value Representation : No need to replace complex molds—simply adjust the bag length and sealing/cutting positions quickly via programming, enabling… Seamless switching between products of different capacity specifications (e.g., from 100 ml to 1000 ml) This significantly reduces changeover time, meeting the modern production trend of "small batches and diverse product varieties."

2. Precise Intelligent Control System

Core Technology : Servo motors combined with pneumatics The driving mode, by PLC and Human-Machine Interface Touch Screen Perform central control.

Value Representation :

High-precision measurement :The servo system ensures precise filling of sensitive materials such as whipped cream and egg mixture, minimizing waste.

Stably running : Scientific power distribution, low equipment noise, and long service life.

Easy to operate : Parameters can be set with one click, and recipes can be stored and recalled, significantly lowering the technical requirements for operators.

3. World-Class Hygiene and Safety Standards

Core Technology : Food-grade stainless steel material 、 100-Level Cleanroom Laminar Flow Purification Unit 、 Ultraviolet Sterilization Chamber , and supports CIP Automatic Recirculation Cleaning System 。

Value Representation :

From hardware to environment, a comprehensive, all-encompassing protective barrier has been established, effectively preventing microbial contamination.

Especially suitable for applications with high hygiene requirements Pasteurized egg liquid, premium whipping cream, dairy products Etc.

The CIP system enables rapid, thorough, and automated cleaning, eliminating cross-contamination and ensuring product safety between batches.

4. Extensive Material Compatibility

Design Philosophy : Modular design allows for seamless adaptation to the properties of different materials by configuring various pumping systems, such as piston pumps or peristaltic pumps.

Low-viscosity material : Such as juice, soy sauce and vinegar, beverages.

High-viscosity/sensitive materials Such as whipped cream, yogurt, cheese, and jam.

Granular Material Such as fruit pulps with pulp, or spicy sauces.

III. Wide-ranging application areas: Which industries can it create value for?

Based on its robust flexibility and high hygiene standards, this equipment excels particularly in the following areas:

Dairy beverage industry : Bagged packaging for whipping cream, fermented milk, pasteurized milk, yogurt, fruit juice, and plant-based protein beverages.

Seasoning Industry Soy sauce, vinegar, cooking wine, oyster sauce, edible oil, tomato ketchup, and more.

Egg Products and Pre-made Meal Industry : Whole egg liquid, egg white liquid, egg yolk liquid, as well as pre-made egg liquids designed for egg dumplings and fried rice.

The Jam and Dessert Industry : Packaging for various jams, fillings, chocolate spreads, and puddings.

Daily chemical industry Liquid daily-use chemical products such as detergents, hand sanitizers, and shampoos.

IV. Why Choose Saide? – The Core Value It Brings to Businesses

Reduce costs, increase efficiency : One machine replaces multiple lines, reducing initial investment; fully automated production significantly cuts labor costs.

Flexible Response : Rapid product-change capability enables companies to respond agilely to market shifts and take on diverse orders.

Quality Assurance : Clean filling environment and precise metering ensure that the product's taste, flavor, and safety remain consistently excellent.

Risk Management : High-standard hygiene design minimizes the risk of batch contamination, safeguarding your brand reputation.

Conclusion

In an increasingly competitive market environment, the flexibility, intelligence, and safety of production have become the keys to success. Said Bagged Food Fully Automatic Packaging Machine It is precisely an outstanding product born from this very trend. More than just a packaging machine, it serves as a strategic partner for enterprises to enhance their core competitiveness and achieve sustainable development.

Whether you're a well-established brand looking to integrate your production lines, or an emerging enterprise already planning to expand into multiple product categories, choosing Said means choosing a path that… Efficient, flexible, and reliable The path to modernized production.

TAG:

Related news