Application Fields and Feature Analysis of the Fully Automatic Packaging Machine for Cream Cheese in Composite Film Bags

Fully Automatic Packaging Machine for Cream in Composite Film Bags: In-Depth Analysis of Application Features and Industry Applications

This article provides a detailed analysis of the core application features of the fully automatic packaging machine for cream-filled composite film bags, including clean filling, high-precision measurement, and flexible production capabilities. It also highlights the machine's extensive use in industries such as baking, tea beverages, and pre-made desserts, offering you expert guidance to help you select the right equipment.

Fully Automatic Packaging Machine for Cream in Composite Film Bags: In-Depth Analysis of Application Features and Industry Applications

Core keywords: Whipped cream packaging machine, composite film bagged whipped cream packaging machine, fully automatic cream packaging machine, cream packaging equipment

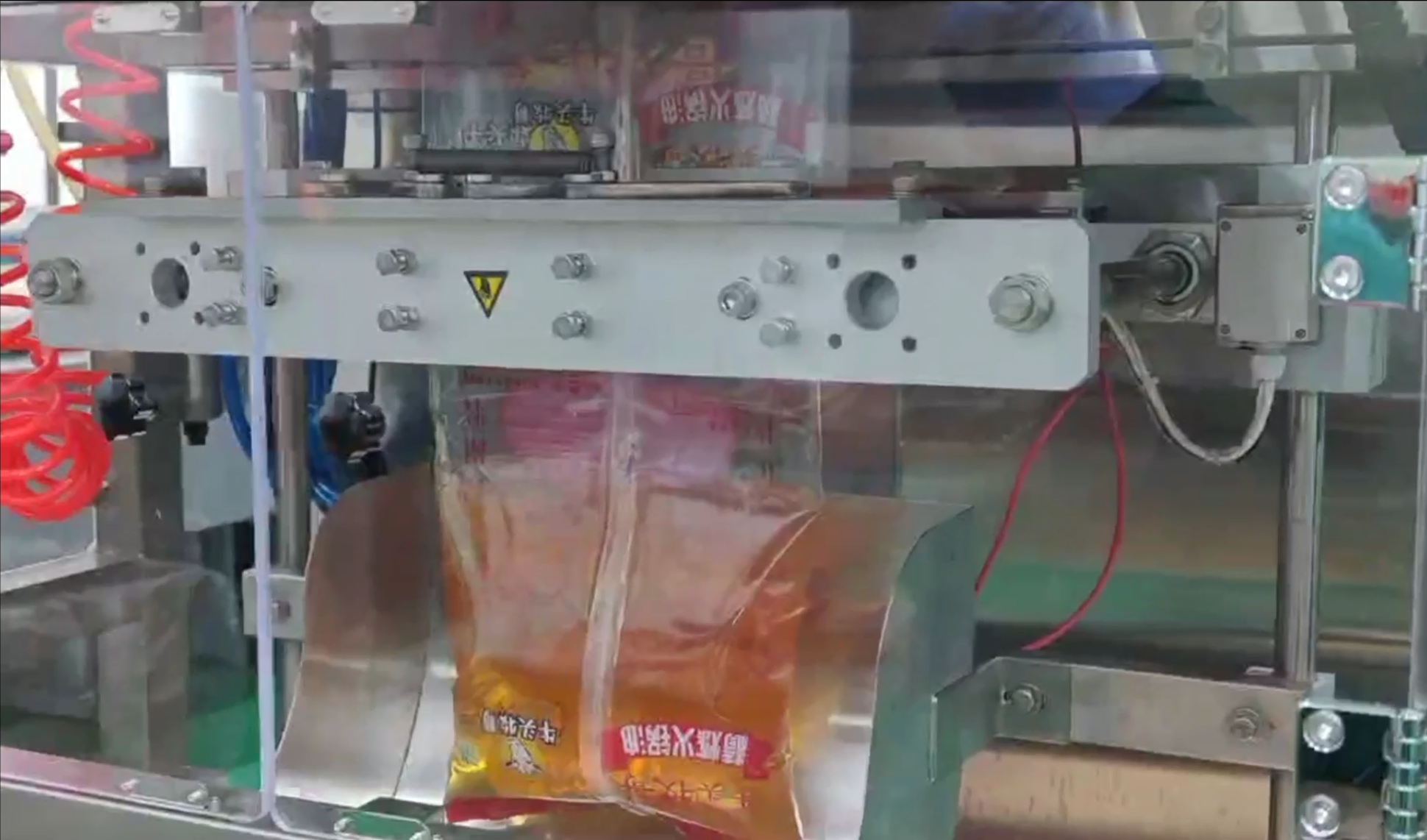

With the explosive growth of the modern tea beverage and baking industries, whipped cream—being a core ingredient—has seen continuously rising market demand. However, traditional canned and boxed formats can no longer meet the diverse commercial needs in terms of both cost-effectiveness and flexibility. Fully Automatic Packaging Machine for Cream in Composite Film Bags , it is precisely its unique advantages that make it the preferred solution for industry upgrades. It not only represents an innovative leap in packaging formats but also serves as a powerful guarantee of both production efficiency and product quality.

I. Core Application Features: Why Is It Specifically Tailored for Whipped Cream?

Whipped cream, being a product with high fat content that is highly susceptible to microbial contamination and physically unstable (easily whipped yet prone to emulsion breakdown), places extremely high demands on packaging equipment. Addressing these challenges, the equipment demonstrates the following four core features:

1. High Hygiene Standards and Sterility / Clean Filling Assurance

- Feature Description : All parts of the equipment that come into contact with materials are made of 316L/304 Stainless steel, designed with no sanitary dead spots, and integrated CIP System. For long-shelf-life products, it can be configured Sterile Filling Chamber , before filling, spray the packaging film with hydrogen peroxide or sterilize it using ultraviolet light, ensuring that the product is packaged in a clean environment to prevent microbial contamination.

- Addressing pain points : Significantly extends the shelf life of whipped cream, ensuring product safety throughout cold-chain distribution.

2. Gentle and ultra-high-precision metering filling

- Feature Description : Adopting Precision piston pump with servo control Perform measurement. This method not only allows filling accuracy to be controlled within ±0.5% to ±1% Of exceptionally high standards, and more importantly, its filling process is smooth and gentle, exerting minimal shear force on the cream.

- Addressing pain points :

- Avoid demulsification : Preventing severe mechanical shocks from disrupting the structure of cream fat globules, which could lead to oil-water separation (resulting in butter formation).

- Avoid incorporating air bubbles. : Ensure the filling process is free of air entrainment to maintain product overrun and consistent texture.

- Cost Control : High precision helps businesses save valuable raw materials.

- Avoid demulsification : Preventing severe mechanical shocks from disrupting the structure of cream fat globules, which could lead to oil-water separation (resulting in butter formation).

3. Perfect synergy with high-barrier composite films

- Feature Description : This device is specifically designed for handling Composite films, high-barrier co-extruded films Optimized for high-end materials. Through precise temperature and pressure control, it achieves strong, seamless heat-sealed edges with high sealing strength and zero leakage.

- Addressing pain points High-barrier packaging effectively prevents oxygen from entering and flavor compounds from escaping, while also blocking UV light—working together to preserve the pure taste and quality of whipped cream.

4. Outstanding flexible and automated production capabilities

- Feature Description : Supports different specifications (from 100-1000g Small seasoning packets for catering 1-25Kg Rapid switching of industrial packaging. From roll-to-machine setup to finished product formation, the entire process is fully automated—requiring no manual intervention—and can be completed directly on the production line. Production date, batch number The inkjet printing.

- Addressing pain points : One-click switching of recipes and specifications to meet customer needs “ Small batches, multiple varieties ” The demand for flexible production significantly boosts capacity while reducing reliance on manual labor and minimizing the risk of cross-contamination.

II. Core Application Areas: Where Is It Driving Industry Transformation?

Based on the features mentioned above, this fully automatic packaging machine is currently playing a revolutionary role in the following fields:

Field One: Baking and Western Pastry Central Kitchen

- Detailed Application Guide : Chain bakeries and central factories require large quantities of whipped cream in various sizes for making decorated cakes, mousses, éclairs, and more. This equipment can provide from 200ml To 1L A variety of bagged specifications are available, making it convenient for different stores to collect supplies as needed.

- Value Representation : Standardized delivery, reduced waste, and ensured consistent quality . The kitchen ingredients are ready-to-use straight from the bag, eliminating contamination and spoilage caused by multiple reuses of traditional large packaging after it’s opened.

Field Two: Modern Tea Drinks and Coffee Chain Brands

- Detailed Application Guide : Products like milk tea, milk foam tea, and coffee artistry place enormous demand on whipping cream. The equipment can produce items suitable for bar counters. Small bag , allowing store staff to quickly retrieve and measure ingredients, significantly boosting cup-serving efficiency.

- Value Representation : Achieved Standardized production, simplified operations , ensuring the consistent taste of every beverage, has been the unsung hero behind the brand's rapid expansion.

Field Three: Pre-fabricated Desserts and Ice Cream Industry

- Detailed Application Guide : A light cream ingredient used for producing pre-made desserts such as mousse cups, tiramisu, and ice cream—typically supplied in large industrial packaging. Fully automatic bagging offers a lighter and more cost-effective solution compared to metal cans.

- Value Representation : Reduce packaging material costs and optimize cold-chain logistics efficiency. , providing a stable and reliable supply of raw materials for large-scale industrial dessert production.

Field Four: Brand Cream Producers and Dairy Enterprises

- Detailed Application Guide : Targeting the end-consumer market or small bakeries, we produce retail-ready, bagged whipping cream products. The high-barrier composite film packaging delivers superior shelf life compared to conventional plastic bottles.

- Value Representation : Building Differentiation, High Quality Brand image, expanding sales channels, and enhancing product competitiveness.

Conclusion

Fully Automatic Packaging Machine for Cream in Composite Film Bags Its success stems from its Deeply aligns with the characteristics of whipped cream products and the demands of the modern food industry. It perfectly addresses the industry's core pain points in terms of quality, cost, and efficiency—through hygiene assurance, precise and gentle filling, high-barrier packaging, and flexible automation. Investing in such a specialized piece of equipment is a strategic decision that enhances core competitiveness and drives business growth, making it an essential move for any cream producer or foodservice supply-chain enterprise aiming to stay ahead in today’s fiercely competitive market.

TAG:

Related news