Sed III SD-F Bagged Egg Liquid Automatic Packaging Machine: A Comprehensive Analysis of Application Features and Industries

Bagged Egg Liquid Packaging Machine ⅢSDF : A Comprehensive Analysis of Application Features and Domains

Core keywords: Bagged Egg Liquid Packaging Machine ⅢSDF , whole egg liquid packaging machine, egg liquid packaging equipment, egg liquid packaging solutions

In the wave of automation in the food industry, specialized packaging equipment tailored for specific materials is becoming a powerful tool for businesses to reduce costs and boost efficiency. Bagged Egg Liquid Packaging Machine ⅢSDF , it is precisely a benchmark product in the field of egg liquid processing. This is not a general-purpose liquid packaging machine, but rather a specialized solution that deeply aligns with the physicochemical properties of egg liquids and meets modern food safety production standards. This article will focus on its core features. Application Features With the vast Application Areas , providing a comprehensive analysis of its true value.

I. Application Feature: Why Was It Specifically Designed for Egg Mixture?

Egg liquid has Prone to microbial growth, exhibits significant viscosity fluctuations, easily foams, and is sensitive to oxygen. and other characteristics. ⅢSDF The model's design perfectly addresses these challenges, showcasing the following four distinct features:

1. Outstanding hygienic design

- Feature Description : The parts of the equipment that come into contact with materials are entirely made of 304/316 Stainless steel , with a smooth surface and no sanitary dead spots. Equipped with comprehensive features CIP (In-situ cleaning) systems enable fast, thorough, and automated cleaning and sterilization without shutting down the equipment, effectively eliminating the risk of contamination by pathogens such as Salmonella.

- Addressing pain points : Fundamentally ensures the biosafety of egg liquid—a highly nutritious yet perishable product—meeting the stringent requirements of food certification systems.

2. Precise and gentle filling technology

- Feature Description : Adopting Servo-driven precision piston filling system This technology ensures that the volume of each bag of egg liquid remains highly consistent, with precision reaching as low as ±0.5–1% Within limits. Meanwhile, the filling process is smooth and stable, preventing harsh impacts and shear forces, which significantly reduces foam formation in the egg mixture and minimizes damage to the protein structure.

- Addressing pain points : It ensures both the fairness of commercial transactions and preserves the functionality (such as whipping rate and emulsifying properties) and aesthetic appeal of the egg mixture.

3. Perfect compatibility with high-barrier packaging materials

- Feature Description : This device is specifically designed for use Composite film, multi-layer co-extruded high-barrier film Optimized for high-end packaging materials, it delivers robust, leak-proof heat sealing that effectively blocks oxygen and ultraviolet light, ensuring superior protection for the packaged contents.

- Addressing pain points : Significantly delays the oxidation, spoilage, and flavor deterioration of egg liquid, extending the shelf life of pasteurized egg liquid to under refrigerated conditions. 30 Even longer than expected, it has significantly expanded the sales radius.

4. Flexible and efficient automated production

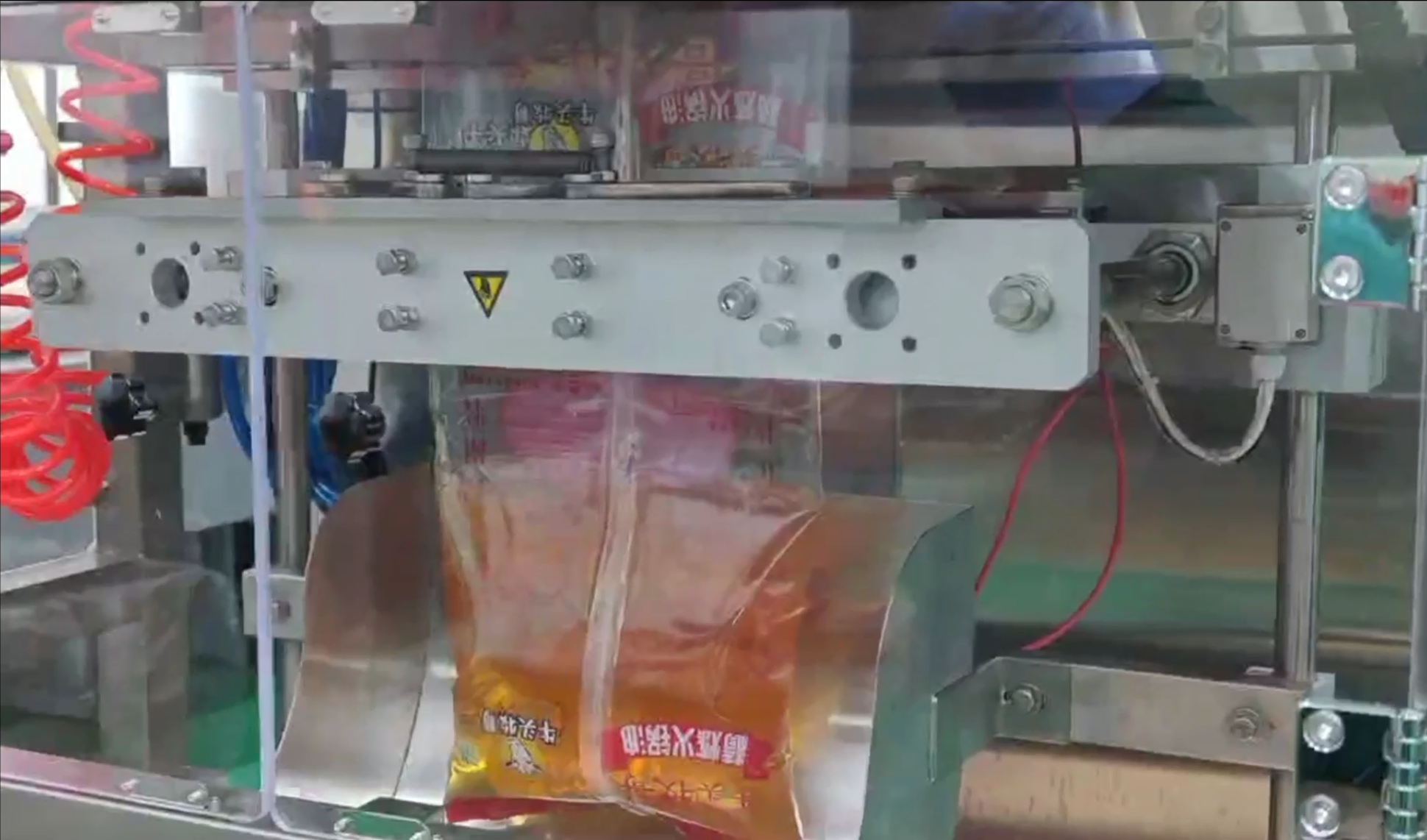

- Feature Description : Supports quick switching between various bag types (such as back-seal and three-side seal) and capacities—from 100-1000g Food and beverage packed into 1-25KG Industrial-grade equipment. Fully automated operation—from roll-fed material loading, bag making, filling, date coding, to finished product output—all seamlessly integrated, ensuring high production efficiency.

- Addressing pain points : Helps enterprises quickly respond to diversified order demands in the market, significantly reducing reliance on skilled operators and thereby saving labor costs.

II. Application Areas: Where Does It Create Value?

Based on the features above, Bagged Egg Liquid Packaging Machine ⅢSDF Plays an indispensable and irreplaceable role in the following fields:

Field One: Industrial Egg Processing Center

- Detailed Application Guide : This is ⅢSDF The most classic application area: Large-scale egg enterprises will process the purchased fresh eggs through cracking, filtering, pasteurization, and homogenization—then directly distribute them via ⅢSDF Perform purification in bagged form.

- Value Representation : Achieved Standardization, Scalability The production of liquid egg products provides safe and reliable basic ingredients for the downstream food industry. It is also the key equipment for replacing traditional bulk liquid eggs and labor-intensive production models.

Field Two: Central Kitchen for Catering and Baking

- Detailed Application Guide Chain restaurants, bakeries, hotels, and group catering suppliers are increasingly using pre-processed egg liquid to enhance efficiency and standardization. ⅢSDF We can provide them with customized, small-sized bagged egg liquid, as well as pre-mixed seasonings like salt and sugar.

- Value Representation : Achieved Precise delivery, reduced costs, and standardized quality . The pre-packaged ingredients in the kitchen are ready-to-use, eliminating hygiene risks, eggshell contamination, and raw material waste caused by manual egg cracking—making them a crucial component in achieving standardization of Chinese cuisine and the industrialization of baking.

Field Three: Pre-made Dishes and Convenience Food Factories

- Detailed Application Guide : In pre-made products such as egg dumplings, fried rice combinations, omelets, and instant noodles, egg liquid is the core ingredient. ⅢSDF The packaged egg liquid can serve as a ready-to-use ingredient, seamlessly integrating with the subsequent automated production line.

- Value Representation : Simplified the production process while ensuring ingredient safety and freshness. This makes large-scale, standardized production of pre-made dishes possible, helping companies rapidly expand into new markets.

Conclusion

In summary, Bagged Egg Liquid Packaging Machine ⅢSDF Its success lies in its “ Features ” With “ Field ” Precise matching Its high hygiene standards, precise filling capabilities, superior barrier compatibility, and flexible automation directly address the core challenges across various egg-liquid processing sectors. Whether used as a basic ingredient, central kitchen component, or key element in pre-made dishes, it leverages its expert performance to serve as a powerful engine for ensuring food safety, boosting production efficiency, and driving the advancement of the entire egg-liquid industry.

TAG:

Related news