A Comprehensive Guide to Bagged Fresh Milk Packaging Machines: Principles, Advantages, and Selection Tips

A Comprehensive Guide to Bagged Fresh Milk Packaging Machines: Principles, Advantages, and Selection Tips

A deep dive into bagged fresh milk packaging machines. Discover their working principles, core advantages, how to choose the right equipment, and their critical role in safeguarding fresh milk quality while boosting production efficiency. Providing dairy companies with a professional purchasing guide.

A Comprehensive Guide to Bagged Fresh Milk Packaging Machines: Principles, Advantages, and Selection Tips

Core keywords: Bagged fresh milk packaging machine, fresh milk packaging machine, milk packaging equipment, bagged milk production line

In today's increasingly competitive dairy market, Fresh Milk in Bags With its low cost, convenient portability, and easy-to-open features, it continues to hold a significant market share—particularly in everyday household consumption and the foodservice channel. And behind it all lies an efficient, dependable "behind-the-scenes hero" that makes it all possible. —— Bagged Fresh Milk Packaging Machine It is not merely a simple filling and sealing device—it is, in fact, the core component that ensures the quality of fresh milk and determines production efficiency. This article will take you on a comprehensive journey to understand this crucial equipment.

I. Bagged Fresh Milk Packaging Machine: The Heart of the Fresh Milk Industry “ Escort Provider ”

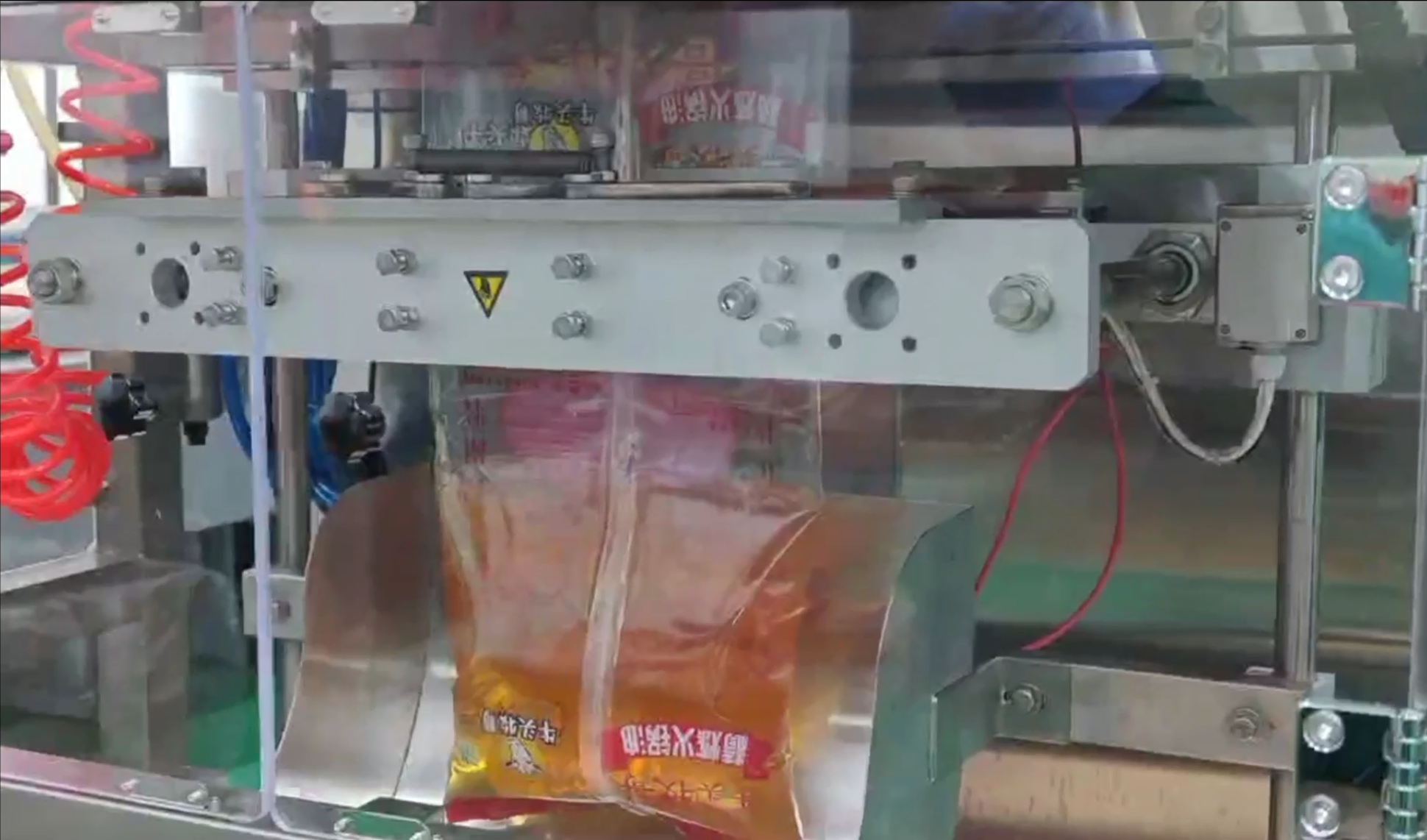

Bagged Fresh Milk Packaging Machine It is an automated packaging device specifically designed for liquid milk—particularly pasteurized milk that requires refrigeration. It utilizes roll-form composite packaging film (commonly PE/ Nylon /PE Structure-based, automatically completed Bag making, filling, date printing, sealing, and cutting A series of processes that ultimately produce the commonly available bagged fresh milk products on the market.

Its core mission lies in achieving, with the highest possible efficiency, Sterilization Or Purification Filling ensures that the fresh milk's flavor and nutrients are preserved to the fullest extent, while also guaranteeing product safety throughout cold-chain distribution.

II. The Three Indispensable Core Advantages

Why has bagged fresh milk remained popular for decades? The packaging machine has played a crucial role:

- Maximize cost reduction

- Packaging materials are low in cost. Compared to pre-formed roof boxes, glass bottles, or plastic bottles, roll film offers a significantly advantageous cost advantage.

- Warehousing and logistics costs are low. : The roll film takes up minimal space, maximizing storage efficiency; the finished milk pouches have a flat shape, allowing cold storage facilities of the same volume to hold more products—and making transportation significantly more efficient as well.

- Packaging materials are low in cost. Compared to pre-formed roof boxes, glass bottles, or plastic bottles, roll film offers a significantly advantageous cost advantage.

- Outstanding preservation performance

- Professional packaging films offer excellent oxygen-barrier and light-shielding properties, effectively preventing vitamin loss and flavor deterioration in fresh milk caused by oxidation and exposure to light.

- The equipment employs reliable heat-sealing technology, ensuring strong and secure seals with excellent leak-proof performance, thereby preventing any leakage and safeguarding the hygiene and safety of the product during transportation and sales.

- Professional packaging films offer excellent oxygen-barrier and light-shielding properties, effectively preventing vitamin loss and flavor deterioration in fresh milk caused by oxidation and exposure to light.

- Highly Efficient Automated Production

- Fully automated operation ensures a seamless process—from roll film to finished product—achieving production speeds of over 100 bags per minute, perfectly meeting the daily output demands of large-scale dairy enterprises.

- One person can operate multiple production lines, significantly reducing labor costs and the risk of contamination caused by human intervention.

- Fully automated operation ensures a seamless process—from roll film to finished product—achieving production speeds of over 100 bags per minute, perfectly meeting the daily output demands of large-scale dairy enterprises.

3. How does a bagged fresh milk packaging machine work?

Its workflow is a meticulously coordinated automated process:

- Thin-film Traction and Positioning : The equipment automatically pulls the packaging roll film, precisely tracking the film's position via a photoelectric eye. Color scale , ensure that the pattern on each bag is aligned for a neat and tidy appearance.

- Molding and Longitudinal Sealing :The film is folded into a preset bag shape—such as the common back-sealed pouch—using a forming device, and then sealed longitudinally with a heat-sealing strip, creating a continuous tubular structure.

- Top Sealing and Cutting :The lateral sealing mechanism performs thermal pressing in the vertical direction, completing two actions: sealing the top of the current bag and the bottom of the previous bag, while simultaneously cutting through the middle to create a single unit. The bottom is sealed. The independent empty bag.

- Opening the Bag and Filling : Empty bags are delivered to the filling station, where the filling valve is precisely inserted into the bag opening, enabling highly accurate… Peristaltic pump Or Quantitative Cylinder Pour the measured amount of fresh milk into the bag. The entire process is contactless and drip-free, preventing cross-contamination.

- Exhaust and Sealing After filling, the equipment will expel the air at the top of the bag—either by compression or inflation—to minimize oxidation, followed immediately by the final transverse sealing.

- Date Coding and Output During the filling or output process, a coding machine is used to print information such as production date and shelf life at the designated location on the bags, after which the finished products fall into the collection bin.

4. How to Choose a Suitable Bagged Fresh Milk Packaging Machine?

Selecting equipment is a critical decision for dairy enterprises, requiring careful consideration of the following points:

- 1. Production Capacity and Speed : Based on your daily production requirements, select the equipment speed that matches (e.g., bags) / Minutes.) Never blindly pursue high speed while neglecting stability and cost.

- 2. Filling Accuracy and Hygiene Level :

- Precision : It is essential to choose a high-precision filling system (such as a servo-driven peristaltic pump) to ensure consistent volume in each bag and prevent “ Underweight and undersized ”。

- Health : The parts of the equipment that come into contact with the material must be 316/304 Stainless steel should be designed without sanitary dead spots, making it easy to clean and sterilize. CIP The online cleaning function is a significant plus.

- Precision : It is essential to choose a high-precision filling system (such as a servo-driven peristaltic pump) to ensure consistent volume in each bag and prevent “ Underweight and undersized ”。

- 3. Packaging Form and Film Width : Determine the bag specifications you need (such as 200ml, 500ml, 1L ) and bag-type (back-sealed, side-sealed) designs, ensuring the equipment model matches accordingly.

- 4. Equipment Stability and After-Sales Service :

- Stability : Examining the core components of the equipment (such as servo motors, PLC , the brand and quality of heat-sealing components directly determine the failure rate and lifespan.

- After-sales service Whether suppliers can provide timely technical support, spare parts supply, and repair services is crucial for ensuring continuous production.

- Stability : Examining the core components of the equipment (such as servo motors, PLC , the brand and quality of heat-sealing components directly determine the failure rate and lifespan.

Conclusion

Bagged Fresh Milk Packaging Machine It is a crucial link connecting high-quality milk sources with consumers' tables. Far from being just a cold, impersonal machine, it is strategically vital for dairy companies—enabling them to enhance product competitiveness, ensure food safety, and achieve cost reductions while boosting efficiency. Investing in a technologically advanced, highly reliable machine Bagged Fresh Milk Packaging Machine , which means equipping your fresh milk business with a powerful engine, enabling it to thrive steadily and go the distance in the fierce market competition.

TAG:

Next page

Related news